How to solve if the regular longitudinal scratches were found in the glass panel surface during glass tempering process?

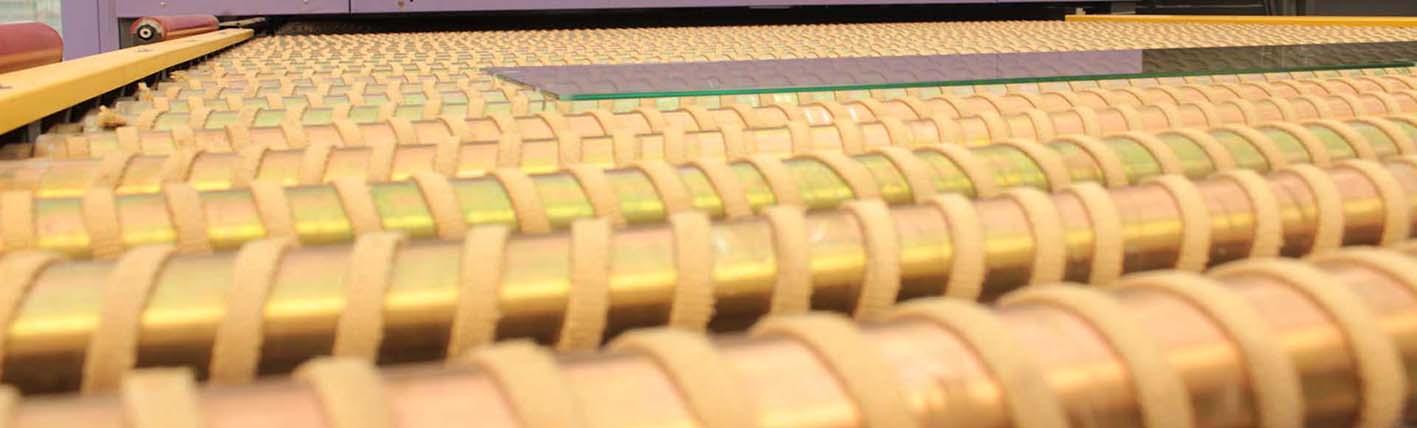

1. Foreign objects resided on the conveying rollers of the glass tempering furnace would cause the regular scratches on the glass surface. As the location of a foreign object is fixed, the scratches on the glass will show a regular pattern. We can check the state of the rollers in the heating oven and cooling section and tackle the issue accordingly.

2. If the kevlar rope or sleeves around the quenching rollers in the cooling section of the glass tempering furnace is damaged, the steel drive rollers in the tempering section will directly contact the hot glass surface and cause scratches on the glass when the glass is in motion. In that case, we must replace the damaged kevlar rope or sleeves immediately.

3. The failure of the furnace door could also cause damage to the glass surface. The opening of the door may have come into contact with the glass surface. If that happens, we should check the door for malfunction and adjust the opening height of the door.

4. When the heating elements or thermocouple in the upper part of the furnace come off, it may also cause different degrees of scratching on the glass surface. In that case, we must stop the furnace to repair the faulty heating element or thermocouple.

Post time: Apr-18-2022